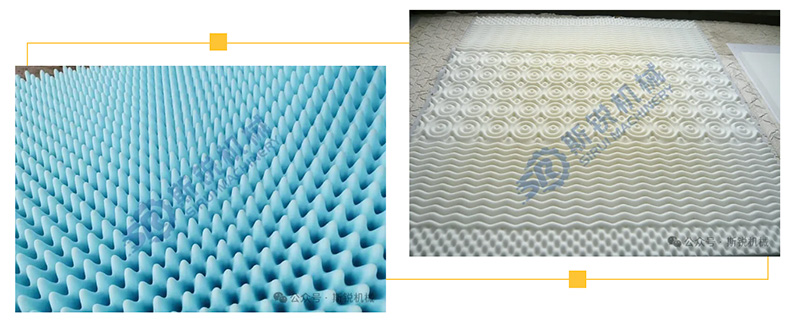

In industries such as seat cushions, mattresses, and soundproofing materials, the deep processing of sponges directly determines product competitiveness. The traditional cutting method has low efficiency and a single flower shape, while the Slei sponge press integrates high-precision pressing and cutting, efficiently cutting the sponge into customized wave, seven zone or five zone pattern shapes, instantly increasing the added value of the product!

Core advantages: Industrial grade efficiency, flexible customization

1. One machine with dual capabilities, doubling efficiency

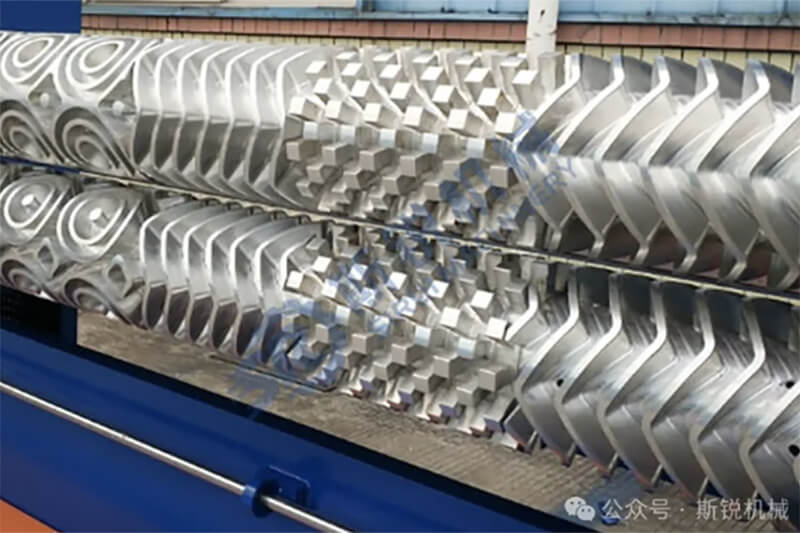

Sponge pressing+sponge cutting synchronized completion: Customized flower shapes (such as waves, stripes, etc.) are achieved through high-strength pressing rollers, accurately cutting the sponge into two layers, eliminating the need for secondary processing.

The cutting width can be selected from 1650/2150/2300mm, or customized according to needs, suitable for large-scale sponge mass production.

Thick and thin, compatible with a full thickness of 0-300mm, it can handle seat cushions, mattresses, and soundproofing cotton in one machine.

2. Depth controllable, versatile flower shape

Automatically adjust the depth of sponge pressing to easily meet customers' differentiated requirements for texture depth.

The flower shaped roller supports customization, allowing for quick switching between patterns such as waves, diamonds, and five zone seven zone patterns, in order to capture niche markets such as high-end home furnishings and automotive interiors.

3. Industrial grade performance, stable output

0-30m/min stepless speed regulation, balancing efficiency and accuracy; Strong power, continuous operation without slowing down.

Automatic feeding system+automatic adjustment of upper and lower pressure rollers, reducing manual intervention, ensuring uniform and consistent sponge cutting depth.

Application scenarios: from home furnishings to engineering, with full coverage of requirements

In the home furnishing field, we produce wave and flower shaped mattresses and cushions to enhance breathability and comfort, and create differentiated selling points.

Automotive Interior: Customized soundproof sponge and seat filling layer to meet the lightweight and noise reduction needs of car manufacturers.

Acoustic Engineering: Cutting shaped soundproof cotton for use in audiovisual rooms and recording studios, accurately adapting to installation scenarios.

Why choose the Siri Sponge Forming Machine?

Accurate pressing: The aluminum alloy pressing roller is engraved by computer, and the lifting is controlled by servo. The pressing effect is smooth and full, not easy to rebound, and suitable for various sponge densities and shapes.

Customized on demand: Customize molds according to different product sizes and shapes of customers, provide technical support and training services, and ensure rapid production.

Engineer's favorite: simple operation interface, intuitive parameters, even beginners can quickly get started.

An industrial tool specially designed for sponge compression cutting

If you have a need for sponge forming processing, Sirui Machinery has multiple sponge wave forming machines and sponge forming cutting machines to provide you with ideal production equipment. Dongguan SIRUI Machinery is a sponge machinery manufacturing enterprise that produces and sells SIRUI brand products. We provide on-site layout, installation, debugging, training, maintenance and other services. Our products are exported to Europe, America, Southeast Asia and Africa. Our service hotline is 86-13450688517. Learn more information and we will provide you with the customized solution you need.