In furniture manufacturing, the cutting accuracy of sponges directly determines the sitting feel of sofas and the comfort of mattresses. Traditional manual cutting or general equipment processing often leads to material waste, low efficiency, and even affects the user experience of the final product.

How to make each sponge perfectly fit the design requirements? These 4 "tailor-made" sponge cutting equipment may be the answer!

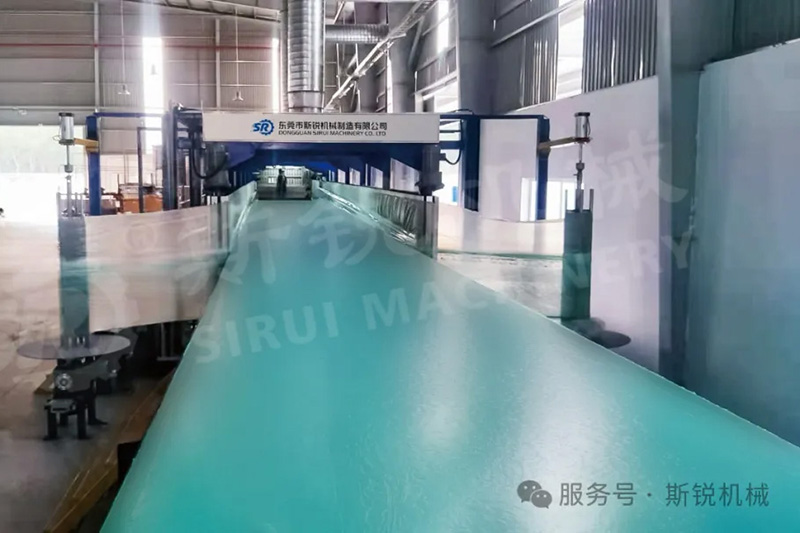

1. SR-A04 fully automatic angle cutting machine: the ultimate solution for complex sponge angle cutting

Industry pain points:

Parts such as sofa armrests and backrests require multi-angle cutting of sponges. Traditional equipment adjustment is time-consuming and the accuracy is difficult to guarantee.

Large operating errors lead to mismatched sponge splicing, affecting the fit of the finished product.

Technical advantages:

PLC intelligent control: automatic calibration after inputting the angle value, 0-175° adjustment, and accuracy error ≤0.3°.

Efficient cutting: through pre-entered cutting parameters (angle, speed, etc.), reduce manual intervention and improve sponge angle cutting accuracy.

Efficiency comparison:

Traditional workers need 5 minutes/time to adjust the angle manually, while the fully automatic angle cutting machine only needs to enter numbers and complete positioning in 5 seconds, cutting 500 more complex angle parts a day!

Typical applications: high-end sofas, office chairs, car seats and other products that require high-precision angle cutting.

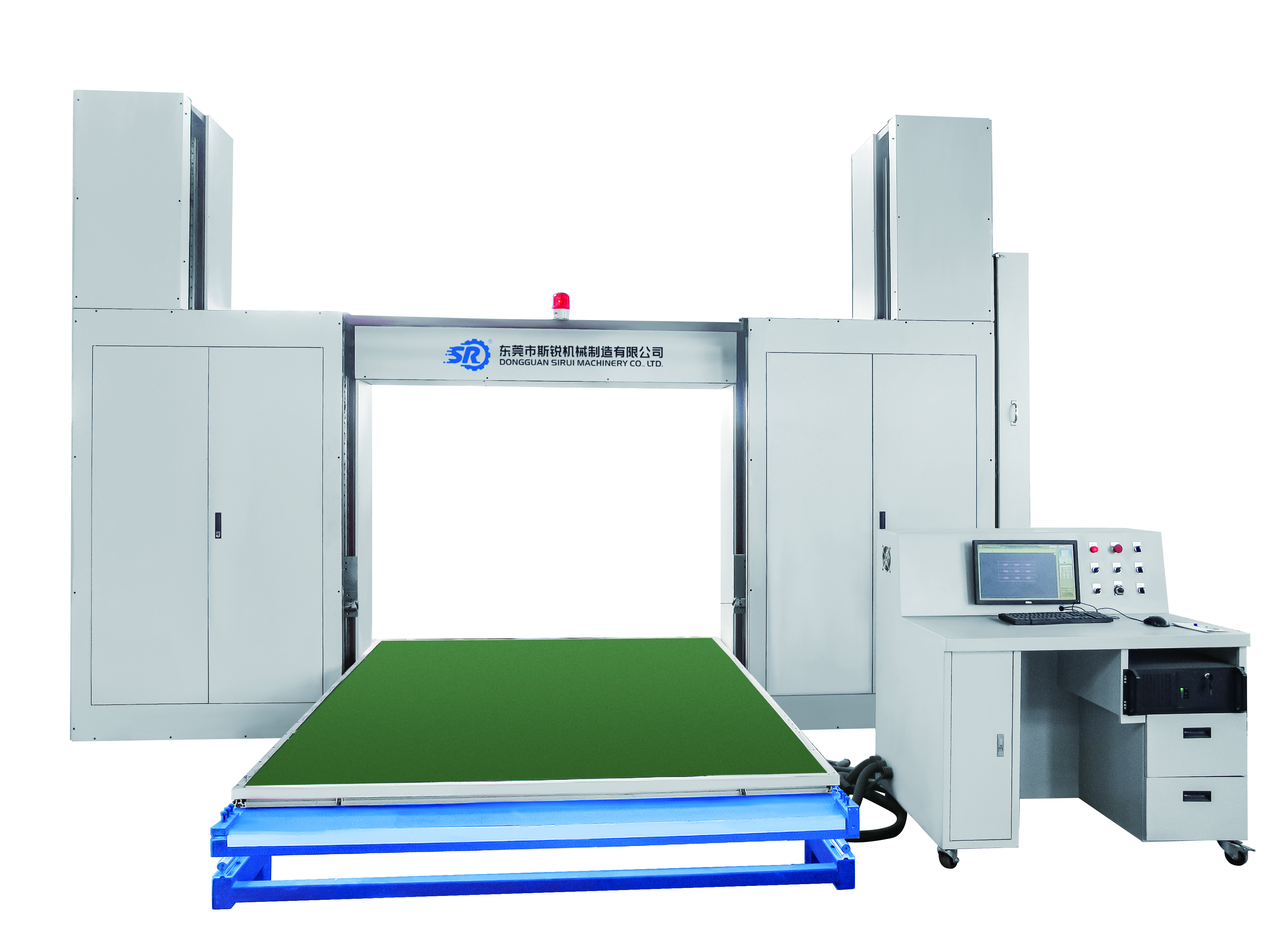

2. SR-MC01/MC02 sponge manual profiling machine: let sponges "grow" curves

Market demand: Consumers have higher requirements for furniture design, and the demand for cylindrical, arc, and pillow-shaped sponges has surged.

Equipment advantages:

Matching market: The profiling machine is like a "mold printer". By replacing different molds, the sponge can be cut into arcs, cylinders and other three-dimensional shapes.

Precise molding: It can be precisely cut along the template or sample contour, suitable for special-shaped sponge processing, ensuring that large-size sponges are cut without deformation and the edges are smooth and burr-free.

Typical applications: Creative furniture, children's products, decorative soft bags and other special-shaped sponge processing manual profiling machines can solve them.

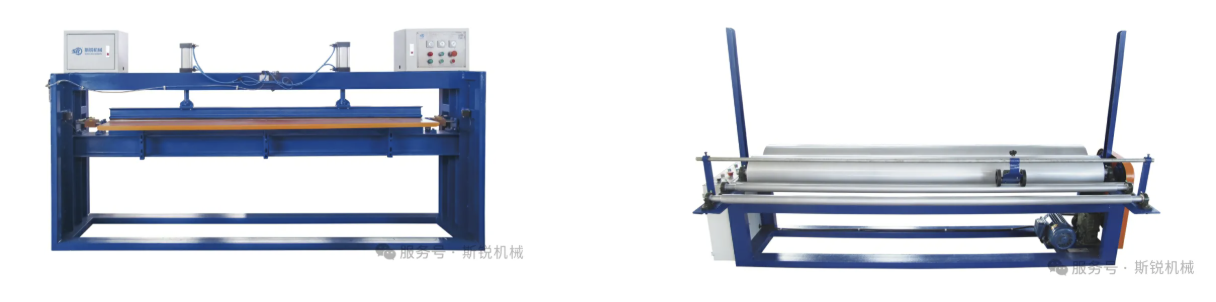

3. Golden combination: SR-J sponge joint machine + SR-RC sponge counting machine - "seamless surgery" of rolled sponge

Secret needs:

The uneven thickness of the sponge joint causes the mattress or sofa cushion to have a bumpy feeling, and the customer complaint rate is high.

Traditional glue bonding has low efficiency and poor environmental protection.

Technical solution:

The joint machine is like a "sponge suture", which controls the pressure and temperature to make the thickness error of the sponge joint ≤0.5mm.

The counting machine works synchronously to ensure that the length of each roll of sponge is consistent, and the sponge is rolled into a finished product synchronously, avoiding manual measurement errors, and is efficient and accurate.

Applicable production lines:

Factories that often have sponge jointing needs for large-scale roll sponge production, customized filling processing, etc.

If you need to cut and join sponges, Si Rui Machinery's various sponge cutting machines can provide you with ideal production equipment. Dongguan Sirui Machinery is a sponge machinery manufacturer that produces and sells the SIRUI brand. It provides on-site layout, installation, commissioning, training, maintenance and other services. Its products are exported to Europe, America, Southeast Asia and Africa. The service hotline is: 86-13450688517. Learn more and we will provide you with the customized solutions you need.